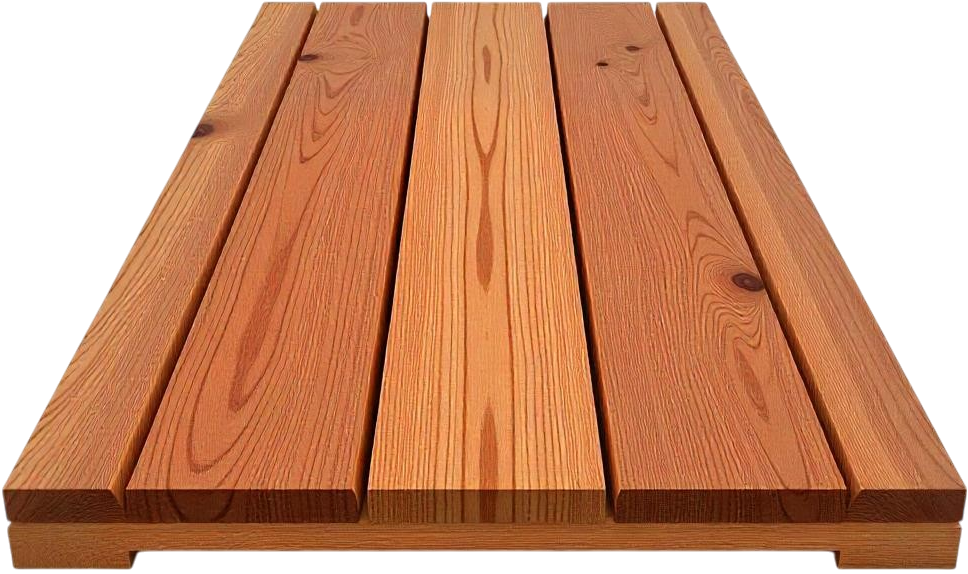

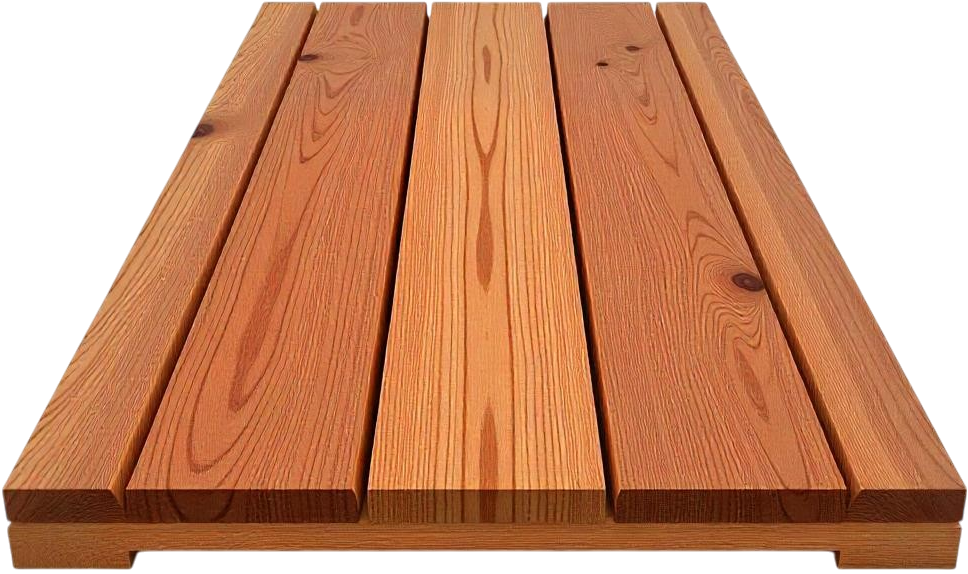

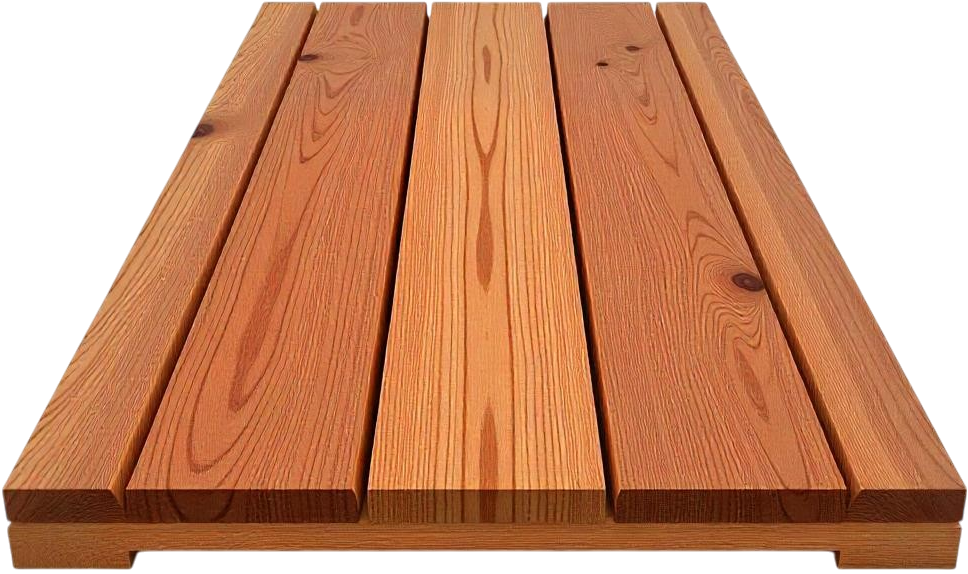

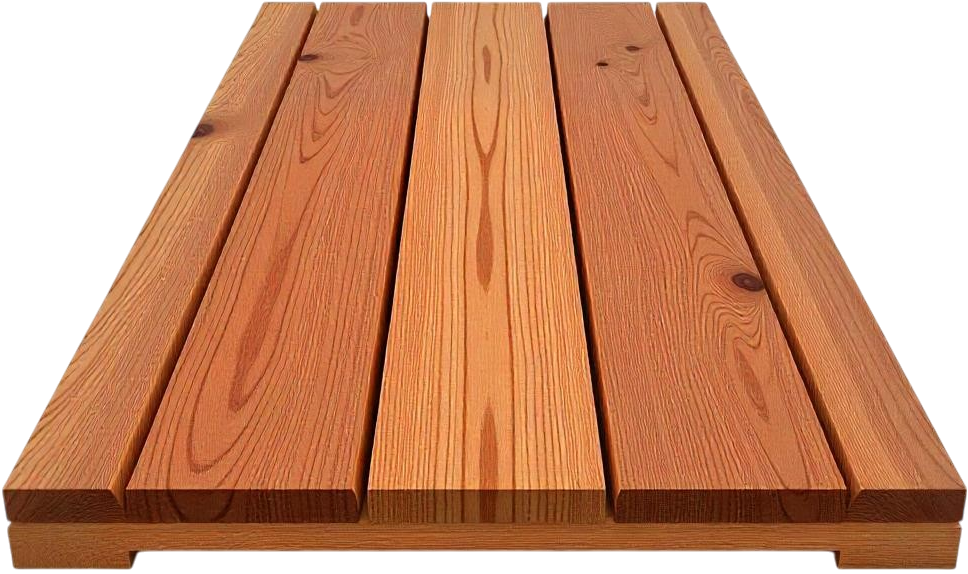

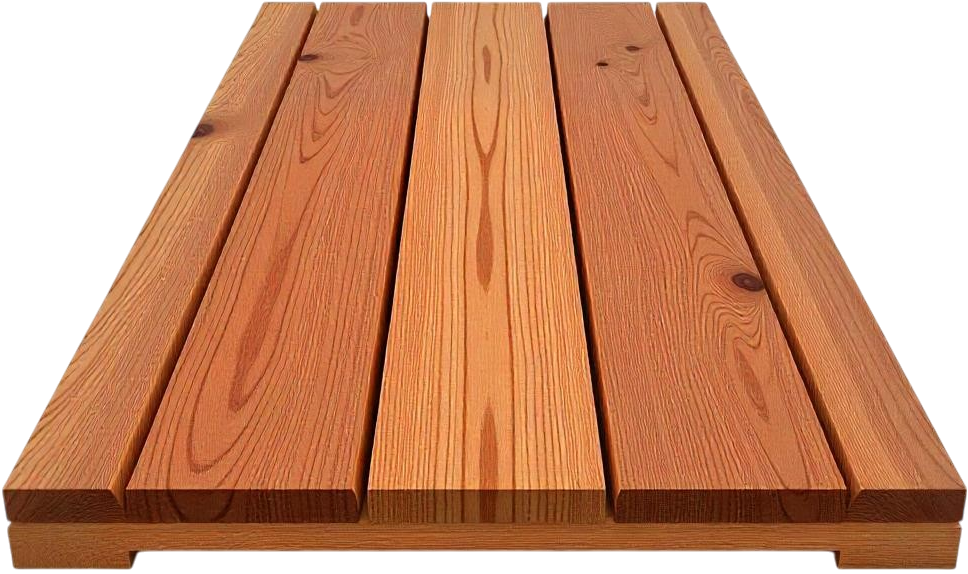

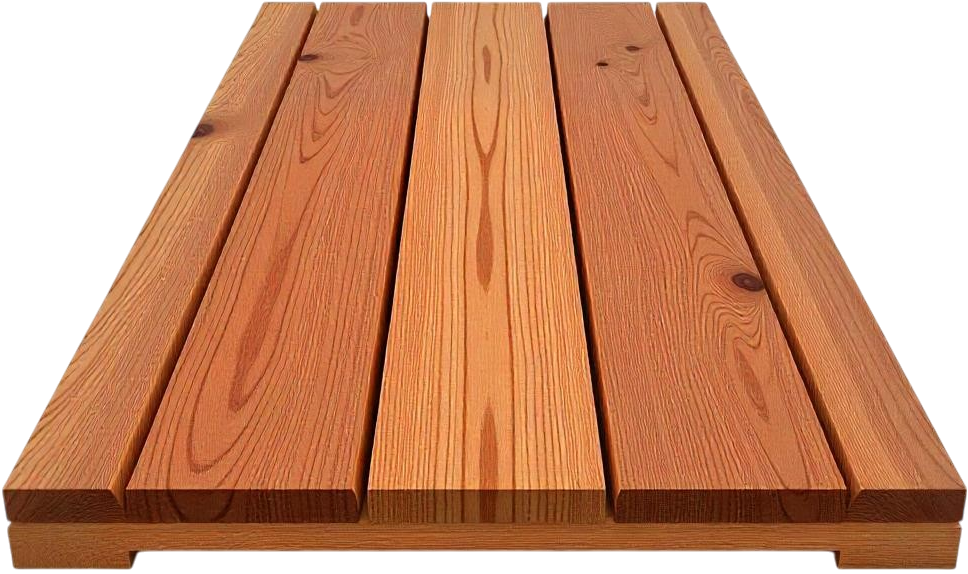

Noawood is a high-performance, thermally modified wood product made from Malaysian tropical timber. It offers exceptional durability, stability, and sustainability for both indoor and outdoor applications.

Made from 100% natural solid wood, offering the authentic look, feel, and warmth.

Noawood requires less frequent refinishing or replacement, saving time and cost in the long run.

As Novawood, we stand by our customers for their special requests and projects.

Novawood supplies value added Ash lumber for companies which want to have the flexibility to produce their own profiles.

Iroko is a large hardwood tree from the west cost of tropical Africa.

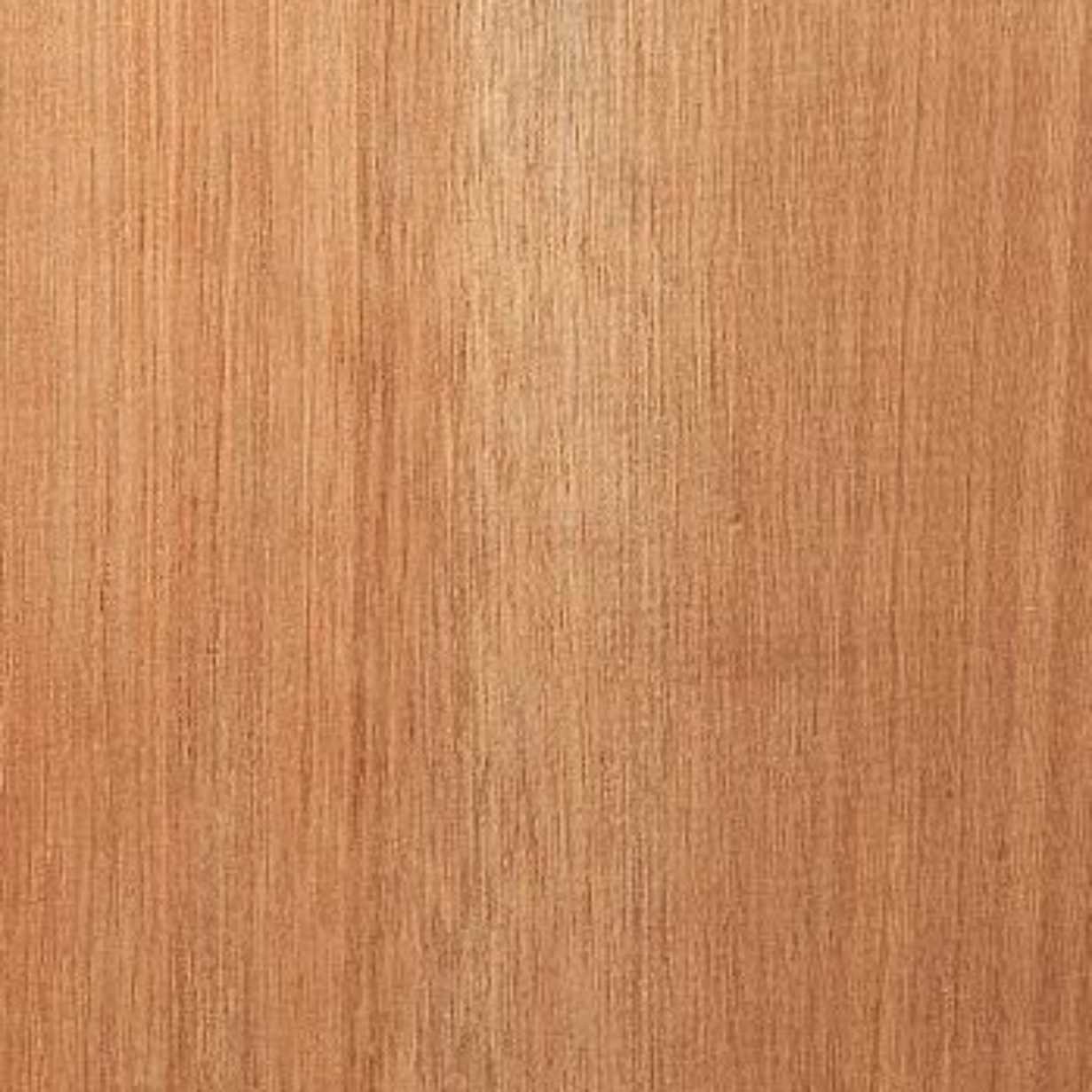

The wood colour is initially yellow but darkens to a richer copper brown over time. The wood is tough, dense and very durable.

Oak wood has a narrow, yellowish white sapwood and a heartwood ranging in color from light brown to dark brown. The grain has a uniform structure, in which the annual rings are clearly visible.

Timber is gently dried at up to 130°C to remove moisture and prepare for safe high-heat treatment.

Wood is heated to 185–230°C in low-oxygen steam conditions, triggering permanent structural and chemical changes.

Cell structure is altered to reduce water absorption, improve decay resistance, and eliminate the need for chemicals.

The timber is gradually cooled, and moisture is reintroduced with steam to stabilise it.

| Thickness | Width (mm) | Length (mm) |

|---|---|---|

| 20/21 | 80/90/112/130/140/150 | 800-3600 |

| 25 | 90/112/130/140/150/160 | 800-3600 |

| 40 | 65/90/112/130/150 | 800-3600 |

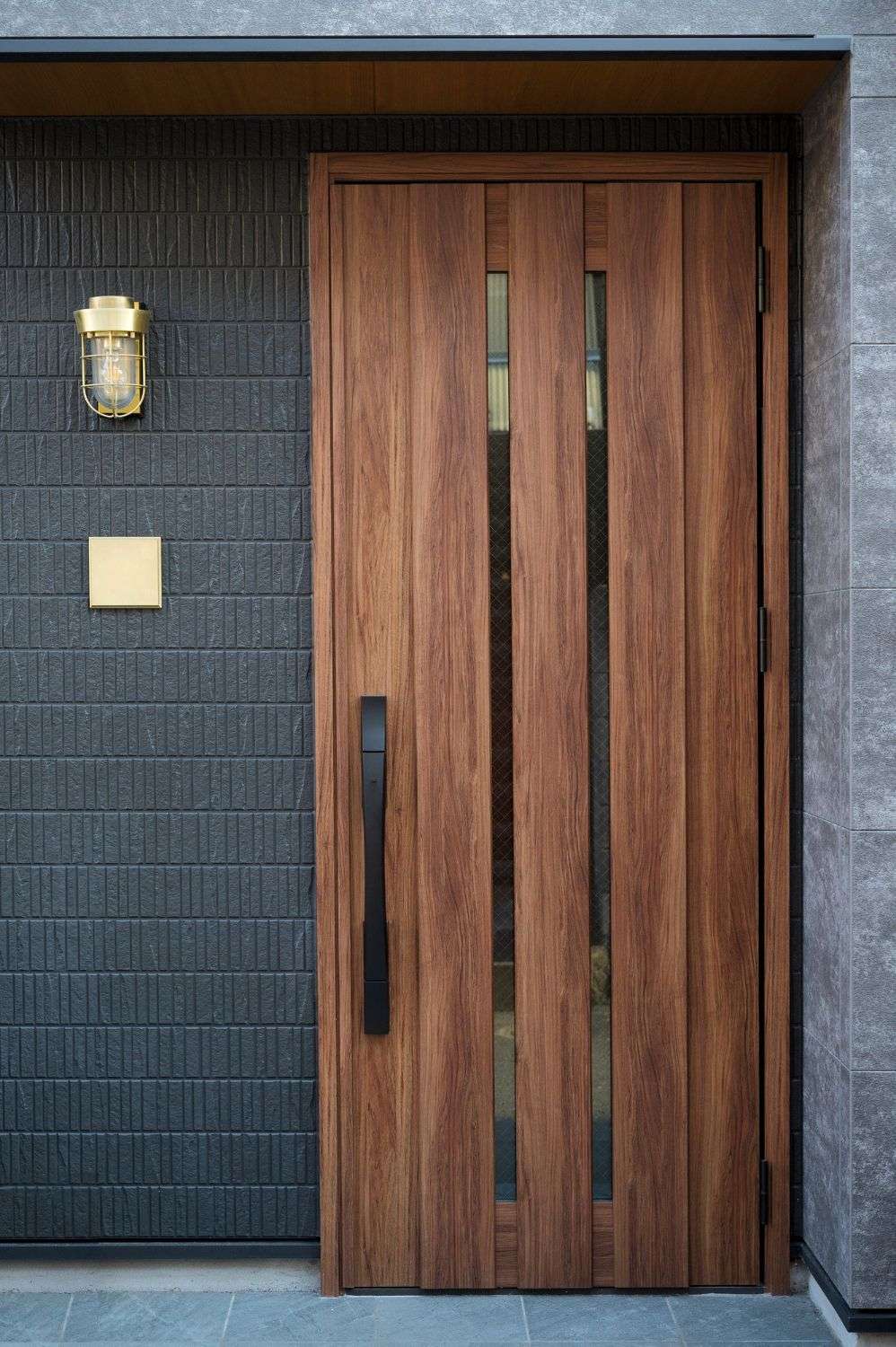

Tropical hardwoods like Seraya and Merpauh have long been valued for joinery, but with thermal modification, they now shine in exterior cladding applications. At Maran Timber, we apply precision thermal treatment up to 230°C to selected species including Seraya, Merpauh, Oak, Eucalyptus Red Grandis, Frake, and more in development.

Tropical hardwoods like Seraya and Merpauh have long been valued for joinery, but with thermal modification, they now shine in exterior cladding applications. At Maran Timber, we apply precision thermal treatment up to 230°C to selected species including Seraya, Merpauh, Oak, Eucalyptus Red Grandis, Frake, and more in development.

Tropical hardwoods like Seraya and Merpauh have long been valued for joinery, but with thermal modification, they now shine in exterior cladding applications. At Maran Timber, we apply precision thermal treatment up to 230°C to selected species including Seraya, Merpauh, Oak, Eucalyptus Red Grandis, Frake, and more in development.

Tropical hardwoods like Seraya and Merpauh have long been valued for joinery, but with thermal modification, they now shine in exterior cladding applications. At Maran Timber, we apply precision thermal treatment up to 230°C to selected species including Seraya, Merpauh, Oak, Eucalyptus Red Grandis, Frake, and more in development.

Tropical hardwoods like Seraya and Merpauh have long been valued for joinery, but with thermal modification, they now shine in exterior cladding applications. At Maran Timber, we apply precision thermal treatment up to 230°C to selected species including Seraya, Merpauh, Oak, Eucalyptus Red Grandis, Frake, and more in development.

Thermally Modified Solid Hardwood (e.g. Merpauh, Mengkulang, Seraya)

EN 113 Class 1 (EN 350). It is highly resistant to decay, fungi, and insects. Suitable for exterior use without chemical treatment.

Varies by species; average 530–700 kg/m³

Thermo wood achieves Euroclass D (EN 13501-1); can be treated for higher performance if required.

The treatment reduces the wood’s equilibrium moisture content to around 4–6% after modification at 230°C.

Toxic-free, no chemicals added during thermal modification.

Fungi, insects, and dimensional movement.

Decking, cladding, façades, soffits, screens, outdoor furniture, and architectural joinery.

Radial

Thermal treatment reduces swelling and shrinkage by up to 50% compared to untreated wood.

Ranges 2.6kN to 4.5kN

10th Floor, Wisma Maran,

28 Medan Pasar,

50050 Kuala Lumpur, Malaysia