With over 15 years of expertise in finger jointing, lamination, and moulding, we’ve grown into one of Asia’s largest laminated scantling manufacturers, trusted by Europe for superior craftsmanship and reliability.

20+ years of expertise in lamination, finger jointing, and moulding for premium timber solutions.

Trusted by European markets for meeting strict performance and visual standards.

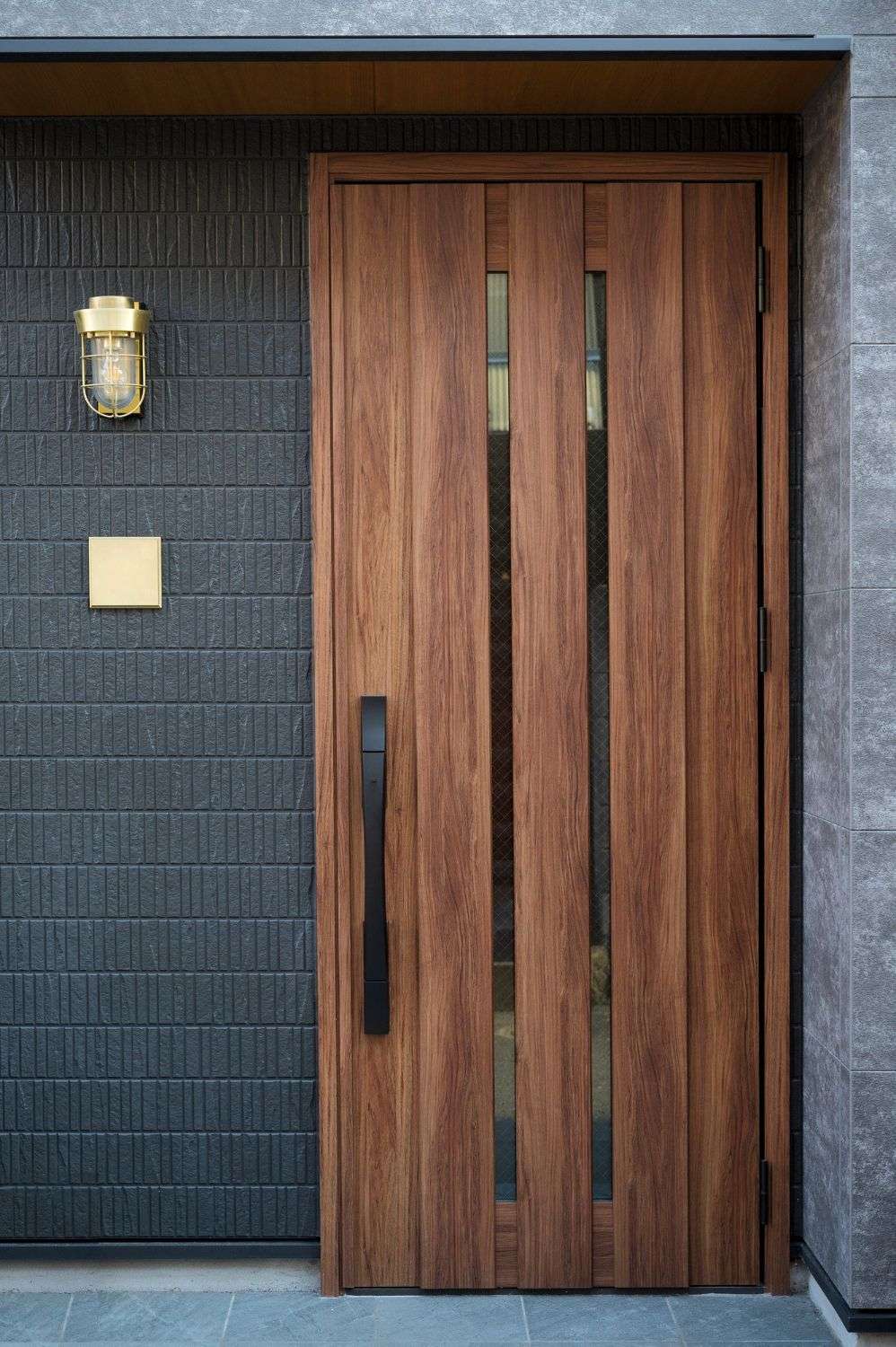

Laminated scantling resists warping and twisting, perfect for doors, windows, and joinery.

High-precision saws that deliver clean, accurate cuts for uniform lamella thickness, ensuring optimal bonding surfaces and reduced material waste.

Standalone systems that join short wood pieces end-to-end with finger joints, creating longer, structurally sound lamella while maximising material yield.

Applies controlled heat and pressure to bond multiple lamella into solid timber sections. This ensures superior adhesion, structural integrity, and long-term performance.

Dedicated profiling machines that shape timber to precise dimensions, enabling smooth assembly and custom profiles with tight tolerances.

Advanced sanding units that deliver consistent, smooth surfaces on finished scantlings, readying them for coating, painting, or final use.

10th Floor, Wisma Maran,

28 Medan Pasar,

50050 Kuala Lumpur, Malaysia