With a capacity of 20,000 m³, Maran Timber specialises in kiln-dried tropical hardwoods that are carefully processed in controlled chambers to reduce moisture, improve stability, and ensure long-term performance across a wide range of applications.

Kiln drying is a controlled process that removes excess moisture from timber to improve its stability, durability, and performance. By carefully managing temperature, humidity, and airflow within drying chambers, the wood is brought to an optimal moisture content suitable for interior and exterior applications.

At Maran Timber, we use precision instruments and continuously upgraded systems to ensure every batch of lumber is dried consistently. This prevents common issues such as warping, shrinkage, and fungal growth, enhancing performance in fabrication and long-term use.

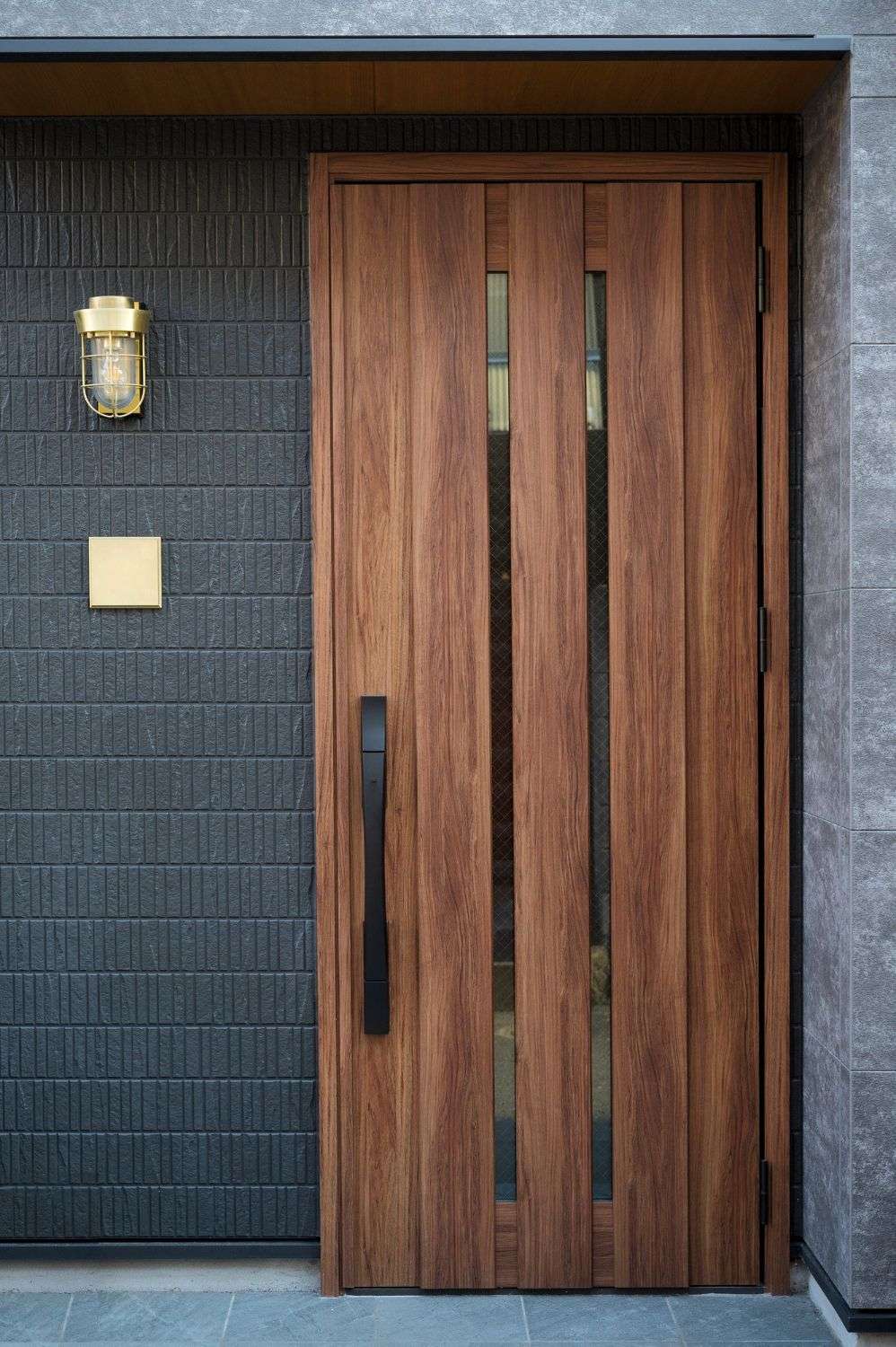

Choose from Meranti, Merbau, Sapele, or Western Red Cedar. We kiln-dry every piece with care, delivering solid, reliable timber you can count on for any project.

Great for interior joinery, furniture, doors, and mouldings.

Over three decades of kiln drying expertise, we ensure consistent product quality and process control.

With 20 drying chambers and a total charge capacity of 1,800m³, we can handle large-scale orders with efficiency.

We operate reliable Kikukawa (Japan) band-saw systems to achieve exceptional straightness and dimensional accuracy.

Our sawn timber is handled by trained sawyers and overseen by experienced supervisors to maintain accuracy and uniformity.

The boards are primed using water based paint and cured in low humidity

The boards are primed using water based paint and cured in low humidity

The boards are primed using water based paint and cured in low humidity

The boards are primed using water based paint and cured in low humidity

The boards are primed using water based paint and cured in low humidity

The boards are primed using water based paint and cured in low humidity

10th Floor, Wisma Maran,

28 Medan Pasar,

50050 Kuala Lumpur, Malaysia